MIB GmbH develops, manufactures and distributes flowmeters and system solutions for liquid media, which are also used specifically in vaccine and drug production and processing.

MIB GmbH develops, manufactures and distributes flowmeters and system solutions for liquid media, which are also used specifically in vaccine and drug production and processing.

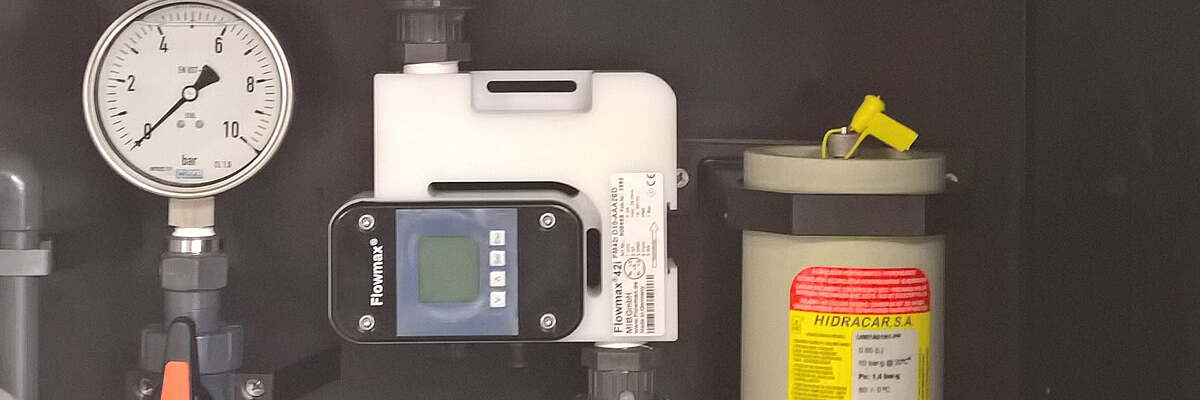

The single use ultrasonic flowmeters “Flowmax 242i” from MIB GmbH set worldwide standards for extremely fast volumetric dosing and filling tasks with documented measurement accuracy. Leading companies in the pharmaceutical industry are already working successfully with these ultrasonic flowmeters.

All sensors are 1% calibrated and supplied with factory calibration certificate.

All Single Use Flowmax 242i bodies have an integrated chip with the calibration data which are automatically transferred to the evaluation electronics during commissioning.

- Unique, single use flowmeter base body with integrated calibration data

- Exact control of dynamic processes

- Exact dosing/re-dosing of chemicals in process tanks (spiking)

- Recording of consumption quantities and controlling of recipes in the process approach (bath management)

- Parallel autarkic process control possible

- Excellent reproducibility

- Measurement of non-conductive and conductive liquids

- Integrated empty pipe and limit value monitoring

- Free pipe cross-section, no mechanically moving parts

- Plug and play function

- All wetted parts certified in PPUTG Class IV iFDA

- All units in contact with the medium are cleaned in a clean room and packaged accordingly

Applications:

Consumption recording of chemicals and demineralized water during initial basin filling and re-spiking, precise mixing of formulations, safe emptying of chemical containers.

MIB GmbH develops, manufactures and distributes flowmeters and system solutions for liquid media, which are also used specifically in vaccine and drug production and processing.

MIB GmbH develops, manufactures and distributes flowmeters and system solutions for liquid media, which are also used specifically in vaccine and drug production and processing.